Why electrolysis?

In short: With an electrolysis device, the required amount of disinfectant can be produced on site from harmless common salt in a simple and inexpensive way and the dosage can be perfectly adjusted

Always the Right Amount of Chlorine

Continuous dosing of hypochlorous acid ensures the water remains clean and safe at all times, providing reliable protection and superior water quality for swimmers.

No Pool Smell or Irritation

Precise chlorine dosing prevents eye and skin irritation while eliminating unpleasant pool odors, making the water perfect even for those with sensitive skin.

Cost Reduction and Safety

Producing active chlorine on-site is significantly cheaper than purchasing traditional chlorine bleach, and reduces the need for pH-regulating products, improving safety.

Membrane electrolysis

The continuous dosing of highly effective chlorine in the form of hypochlorous acid ensures that the right amount of active chlorine is in the water at all times. This means that even people with sensitive skin can bathe in the water. Eye and skin irritation as well as unpleasant swimming pool odours are avoided.

The cost of producing active chlorine with an electrolysis system is significantly lower than the price of purchasing commercially available chlorine bleach. The need for pH-regulating care products is drastically reduced. This reduces the risk of accidents. Thanks to the modern membrane cell technology, the bathing water is not salinised.

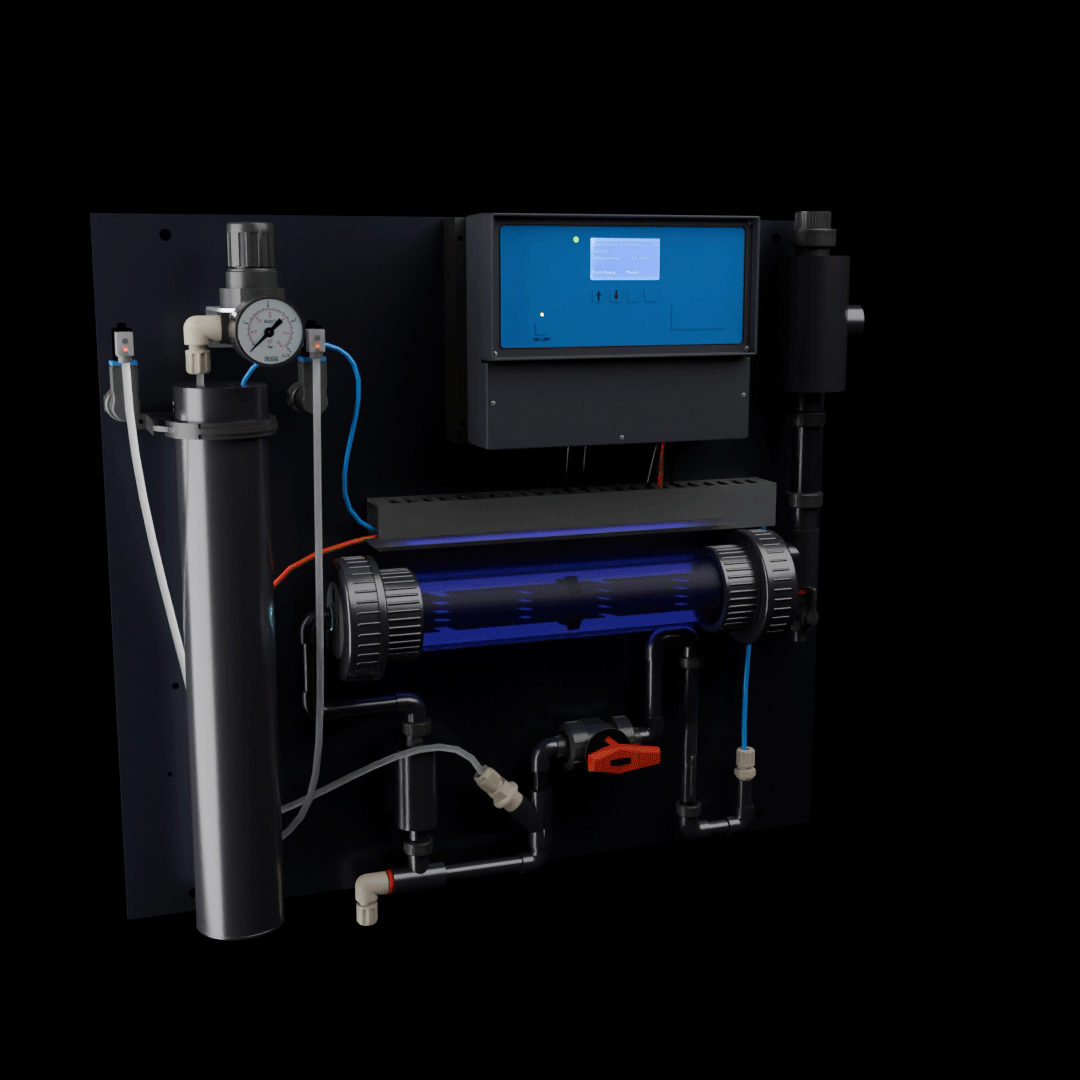

The ECO-a system

Our new ECO-a series offers many advantages of our previous systems combined with new developments and improvements for use in swimming pools. In particular, the advantage of being able to position the salt and product tank independently of the system enables maximum user-friendliness in the planning and operation of your swimming pool.

The integrated control system regulates the output and monitors all operating parameters. Hydrogen produced during the process is separated by a degassing tank and must be discharged to the outside. The fresh hypochlorite is fed into the product tank without an additional pump and can be dosed from there as required.

Versatile Applications for Every Need

Our electrolysis systems are designed to meet the diverse demands of various industries and pool environments. Whether you’re a residential pool owner seeking a reliable, low-maintenance water treatment solution, a pool builder looking for cutting-edge technology to enhance your projects, or a large public swimming facility requiring cost-effective and safe chlorine production, our systems provide the perfect solution. With their flexibility, efficiency, and ease of use, our systems are also ideal for industrial clients looking to streamline water disinfection processes on a larger scale.

Pools

Whether public swimming pools or private pools and swimming ponds. Our membrane electrolysis systems are part of your new swimming experience. Always the right amount of active chlorine in the water, no chlorine odor and easy handling without hazardous chemicals.

Irrigation

Sprinkling and automatic irrigation requires high performance and high standards. This is precisely why EWT is at your side with technology and know-how.

Water features

Public fountains and parks require a high degree of safety and reliability. We offer you exactly the right systems for this with sustainable added value for the environment and operators.

Hotel, Spa & Resort

High-quality components and an innovative technical process not only guarantee you economical operation of your bathing and therapy landscape. Best compatibility without skin irritation and odor.

Swimming ponds

Special water worlds place special demands on the technology. Our product portfolio is perfectly suited to a wide variety of individual projects. Our membrane electrolysis systems meet these special requirements and offer gentle disinfection and a balanced pond climate. We are happy to provide you with our expertise and look forward to becoming part of your project.

Greenhouses

First-class water quality and an economical and reliable infrastructure. No matter how much water your greenhouse requires, we design your water treatment system specifically, economically and for minimum maintenance.

Compact and efficient tube cell electrolysis.

Compact tube cell electrolysis for private swimming pools

How does salt electrolysis work?

The chemical process takes place in the specially designed electrolysis cell. The electric current causes a reaction in the salt solution, producing free chlorine. Inside the reaction chamber, the water is cleaned and disinfected in a hygienically perfect manner. This causes bacteria, algae and other microorganisms to be erased. The system and its performance are specifically designed for the spectrum of your needs.

What types of salt electrolysis units are there?

Membrane electrolysis: The electrolysis cell is separated by a specially developed membrane. The chlorine splits off at the anode and is inoculated into the pool in its purest form. Depending on the type of system, the electrolysis output can be regulated. Any design is conceivable, from small systems for private users to systems for public facilities.

Tube-cell electrolysis: Tubular cell electrolysis saves on transport routes and expensive pool chemicals by producing the required chlorine on site from commercially available salt. The fresh sodium hypochlorite produced in the system is stored directly in the product tank without an additional pump, from where it can be dosed as required.

Compact flow-through cells: These systems are often designed for smaller pools or spas and integrate the electrolytic cell into a compact housing. They are easy to install and require less space, but the performance spectrum of such a system is limited.

What is salt electrolysis?

Salt electrolysis is a method of disinfecting water and is often used in swimming pools and whirlpools, but also in many other applications where the highest demands are placed on water quality. In salt electrolysis, chlorine is produced from the salt dissolved in the water; through an electrolysis process, which then disinfects the water.

Contact our partners for the Netherlands and Belgium

Hydrochemie Conhag B.V.

Industrieweg 94

2651 BD Berkel en Rodenrijs

info@hycon.nl

+31 0105115211