Eco-System

SPECIFICATIONS AND TECHNICAL INFORMATION

ECO-a

| ECO-a 75 | ECO-a 90 | ECO-a 150 | ECO-a 200 | ECO-a 300 | ||

|---|---|---|---|---|---|---|

| Nominal power | g Cl2 / h | 75 | 90 | 150 | 200 | 300 |

| Cell flow rate | l / h | 15 | 18 | 30 | 40 | 50 |

| Salt consumption | g / h | 300 | 375 | 600 | 700 | 1.200 |

| Salt concentration | g / l | 16 | 16 | 16 | 16 | 16 |

| Hypochlorite concentration | g / h | 5 | 5 | 5 | 5 | 5 |

| Hydrogen | g / h | 34 | 41 | 70 | 90 | 140 |

| Dosing pump | l / h | 1,2 | 1,2 | 4 | 4 | 4 |

| CONNECTIONS | ||||||

| Water consumption | l / h | 15 | 18 | 30 | 40 | 50 |

| Power connection | V | 230 | 230 | 230 | 230 | 230 |

| Power consumption | kVA | 1 | 1,2 | 1,5 | 2 | 2,5 |

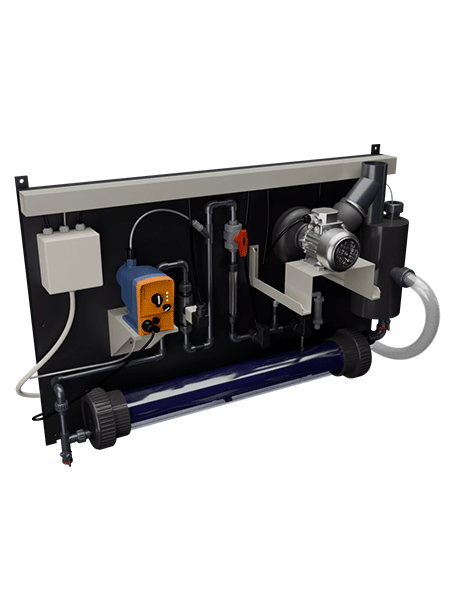

Tube cell electrolysis for the production of low-chlorate sodium hypochlorite solution directly on site. The undivided cells have a long service life and are deliberately kept simple. The PLC controller monitors and regulates all relevant operating parameters and has numerous connection options such as external enable on/off, Modbus IP and Modbus RS485.

Continuous monitoring of the salt concentration prevents unnecessarily high carry-over into the bathing water. With a capacity of 25 to 4,000 g chlorine per hour, the electrolysis system is perfect for small and large disinfection applications.

The units are mounted on a stainless steel frame and can be hung on the wall. A free-standing frame is available as an option. The salt and product tank can be positioned independently of the system. The control cabinet is mounted on the system for sizes 75-300; from size 500 upwards, the cabinet can be positioned anywhere near the system using wall mounting. The hydrogen produced during the process is separated by a degassing tank and discharged to the outside by a fan from size 300 upwards. The fresh sodium hypochlorite is fed into the product tank without an additional pump and can be dosed from there as required.

| ECO-a 500 | ECO-a 1000 | ECO-a 1500 | ||

|---|---|---|---|---|

| Nominal power | g Cl2 / h | 500 | 1000 | 1500 |

| Cell flow rate | l / h | 100 | 200 | 300 |

| Salt consumption | g / h | 1.800 | 3.600 | 5.400 |

| Salt concentration | g / l | 16 | 16 | 16 |

| Hypochlorite concentration | g / h | 5 | 5 | 5 |

| Hydrogen | g / h | 225 | 450 | 675 |

| Dosing pump | l / h | 7 | 19 | 19 |

| CONNECTIONS | ||||

| Water consumption | l / h | 100 | 200 | 300 |

| Power connection | V | 230 | 400 | 400 |

| Power consumption | kVA | 5 | 10 | 15 |

Areas of application

- Outdoor swimming pools public

- Indoor swimming pools public

| ECO-a 2000 | ECO-a 3000 | ECO-a 4000 | ||

|---|---|---|---|---|

| Nominal power | g Cl2 / h | 2000 | 3000 | 4000 |

| Cell flow rate | l / h | 400 | 600 | 800 |

| Salt consumption | g / h | 7.400 | 10.800 | 14.800 |

| Salt concentration | g / l | 16 | 16 | 16 |

| Hypochlorite concentration | g / h | 5 | 5 | 5 |

| Hydrogen | g / h | 900 | 1.350 | 1.800 |

| Dosing pump | l / h | 32 | 2x 19 | 2x 32 |

| CONNECTIONS | ||||

| Water consumption | l / h | 400 | 600 | 800 |

| Power connection | V | 400 | 400 | 400 |

| Power consumption | kVA | 20 | 30 | 40 |

Your advantages at a glance.

- No handling of hazardous chemicals

- No stinging eyes

- No irritation of mucous membranes

- No salinisation

- Maximum and reliable disinfection effect

- Low operating costs

- State-of-the-art membrane cell technology

- Made in Germany

Our team of experts will be happy to help you plan the next steps. Whether it’s a swimming pool, whirlpool or therapy pool – we have the experience and expertise to get your project on the right track.